The Superintendent of the Portland Wastewater Treatment Plant contacted me back in the summer and asked for me to put together a wastewater treatment training program for the employees. This facility is unique in that they have primary clarifiers and it utilizes not only a conventional activated sludge system with clarivacs as their secondary clarifiers but they also have a trickling filter. In recent years they replaced their mixed media filters with microscreens. Primary and waste activated sludge is fed to an anaerobic digester (there is a primary digester that is fed, heated and mixed, that automatically transfers sludge to the secondary digester to make room when pumping) then fed to a sludge holding lagoon. They also use drying beds to dewater their sludge.

It was decided to hold the session in 4-hour intervals, that way they could be in class in the morning and then do their plant work after lunch. The first set of sessions covered the Certification Review Course to introduce a few of the newer operators to the field of wastewater in general and to help a few operators who are studying for their Wastewater Certifications. So we met 4-hours, one day a week for the next 4 weeks to complete this tract. Then we took a short break before meeting for another round of training covering Wastewater Math in two more 4-hour sessions. These sessions centered around using plant data to give the operators useful information on their own facility. When we were done with the first class they cheat sheets for their clarifiers, wet wells, etc. and they figured the volumes and design detention times themselves during class. Then we used lab data to figure solids loadings on clarifiers, sludge ages and how changes in the flow or influent solids can change the detention times and sludge age, F/M ratio, etc. For the final set of sessions, we focused on the hardest workers in the plant – the bacteria – and how certain protozoa and metazoan microbes indicate what bacteria is present. We not only had classroom time, we ended with them loading their own slides and using the microscopes to complete a microscopic “abundance sheet”. A few times an operator scheduled off, but came in for the sessions. Not only are two operators currently studying for the Indiana Department of Environmental Management’s Class II and III or IV Municipal Exams and there are two others now starting to talk about taking the exam as well. It was a pleasure having these sessions and watching the light bulbs continue to go off as they started connecting the dots and understanding how everything works together and how their responses or decisions affect the plant’s performance. It didn’t hurt that the Superintendent provided some of the best local foods for lunch before we left each class. We look forward to continuing the sessions in 2017.

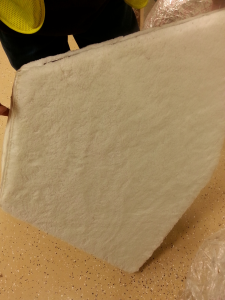

Conventional activated sludge tank