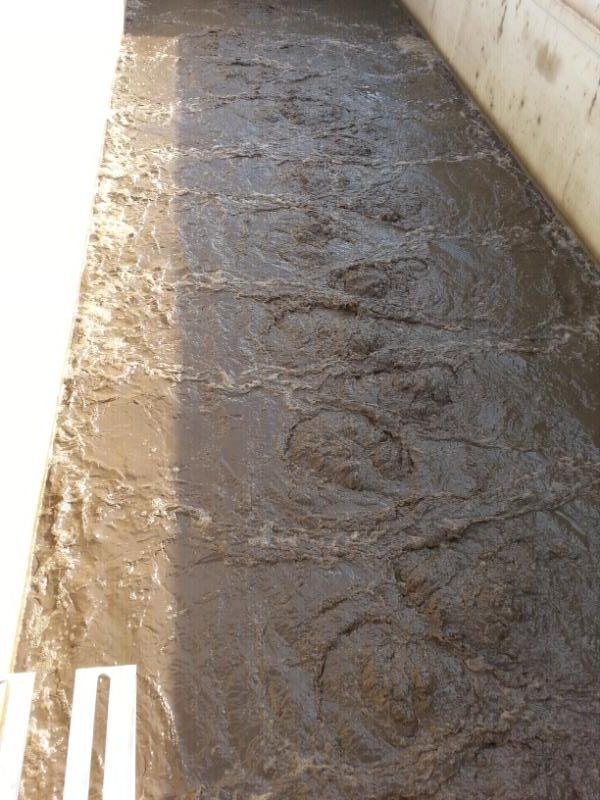

Not that long ago I was able to tour the redesigned Greentown, Indiana Wastewater Treatment Facility. The Certified Operator Bryan Klein was unable to be there for the tour, but both Eric and Scott were more than welcoming and did a great job of explaining the plant. The plant has been updated and resigned from what it was and it has become a “show piece” of newer technology (at least for this area). The plant is designed at 0.58 MGD starts with the headworks which consists mainly of a Hydra-sieve fine screen for trash/grit removal. From there the flow can be directed to an equalization (EQ) tank that holds 450,000 gallons when needed or to an oxidation ditch. The oxidation ditch is the star of the facility and the reason for the tour. This is a different style with separate mixers and diffused aeration in the footprint of an orbital tank. According to Gary Ruston of Wessler and Associates (designing Engineering firm), it allows for much better operator control of D.O. and it helps in winter by keeping the temperature slightly higher by adding “hotter” diffused air and not having rotors splashing (which decreases the temperature). Plus ditches with rotors are limited to about 15 feet deep (the surface rotors won’t mix adequately if deeper than that), but with the separated mixers and diffused air you can go much deeper like a VLR and a smaller footprint if necessary. With them being a major discharger (1.0 MGD or larger) they are or will be dealing with phosphorus limits and are now going to face nitrogen limits in the next 5-10 years, and having the aeration separate from mixing allows flexibility to do anaerobic/anoxic stages or simultaneous nitrification/denitrification in the future. Rotor style ditches were fine and simple to operate for the past 30 years for BOD/nitrification but with upcoming P & N limits and a focus on energy reduction I think there are better ways to do it now, and this style ditch actually has more flexibility than a VLR. The diffusers were placed on a grid system that can be raised and lowered into the tank via a winch/pulley system. Following the oxidation ditch the flow splits to two secondary clarifiers. These are Tow-Bro suction-header with center feed. From there the clear effluent traveled to 1 of 2 polishing ponds and finally to ultra violet disinfection before being released to Brunks Ditch before it finds its way to the Wildcat Creek. The solids are pumped to one of two aerated digesters and then dewatered utilizing the GeoTube process set up in roll-offs.

Greentown also uses Alum (for phosphorous coagulation and precipitation) and they inject it into either the raw wastewater line where the flow enters the ditch from the equalization tank or into the line that takes the flow from the oxidation ditch to the clarifiers.

For more detail regarding the design by Wessler and Associates click here: Greentown WWTP

For more detail regarding the Sanitaire Bioloop click here: SB007_Sanitaire Bioloop Brochure_sm

Please note – there are no pictures of the headwork since most of it is covered with tarps due to the winter temperatures.