A centrifugal pump moves water by the use of centrifugal force. Any time an object moves in a circular motion there is a force exerted against the object in the direction opposite the center of the circle. This would be easier to explain if we use an example consisting of a person with a bucket full of water. If the person swings the bucket in a circle fast enough, the water will stay in the bucket even when it is upside down. The force that holds the water in the bucket is called centrifugal force. If a hole is made in the bottom of the bucket, and it is swung in a circular motion, the centrifugal force will push the water out of the bucket through the hole. The same principle applies when water is moved through a centrifugal pump.

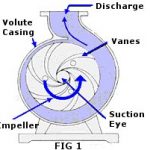

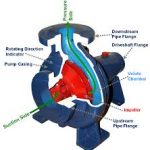

An impeller spins inside a centrifugal pump. It is the heart of the pump. Water enters the center, or suction eye, of the impeller. As the impeller rotates, the veins pick up the water and sling it out into the pump body under pressure. It is the pressure exerted by the vanes that moves the water out of the pump and into the system. The suction created as the water leaves the impeller draws more water into the impeller through the suction eye.

The number of vanes and the sweep of the veins determine the performance characteristics of the impeller. As vanes are added, the impeller will produce higher discharge pressures and lower flows. The same situation applies to increasing the length or sweep of the vanes. Reducing the number of vanes or the sweep of the vanes will increase the flow and reduce the pressure.

Centrifugal pumps designed for pumping wastewater usually have smooth channels and impellers with large openings to prevent clogging.

Impellers may be of the open or closed type. Submersible pumps usually have open impellers and are frequently used to pump wastewater from wet wells in lift stations.