CENTRIFUGAL PUMP COMPONENTS (continued)

Now that the casing is assembled and the piping is in place, we can spin the impeller and begin moving water. Water will enter from the suction side of the volute and will be slung out of the impeller into the discharge side of the volute. Unfortunately, the water will try to pass from the high-pressure side back to the suction side and recirculate through the impeller again.

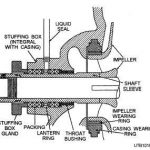

The pump casing could have been machined to close this gap, but the fit would become worn and widened over time. To prevent this internal recirculation, rings are installed between the pump and the impeller that reduce the clearance between them to as little as 0.010″. Unlike the casing, these rings are removable and can be replaced when they become worn. Because they wear out and get replaced, they are called wearing rings.

There is another area of the pump that will require some attention. Something must be done to plug the hole where the shaft enters the pump casing. This is a place where water can leak out and air can leak into the pump. Neither of these situations is acceptable. The part of the pump casing that the shaft passes through is called the stuffing box. It’s called the stuffing box because we are going to stuff something in the box to keep the water in and the air out. This “stuffing” will usually be rings of pump packing. Several rings of packing are placed in the stuffing box.

A metal insert ring fits on top of the stuffing box and is used to adjust or tighten the packing down to minimize water leakage. It is called a packing gland. Since the packing rings touch the shaft sleeve as it rotates, friction and heat are generated in the stuffing box when the pump is running. Water is generally used to cool the packing rings during operation. This means that some water must leak out of the stuffing box when the pump is running. Water may simply be allowed to leak through the packing rings from inside the pump to cool them.

This water must come from the low-pressure side of the pump and may not be under enough pressure to leak past the packing rings when the packing gland is properly adjusted. If this is the case, high-pressure water from the discharge side of the pump may have to be piped into the stuffing box. Seal water piping is used to supply this water to the packing. The seal water enters the stuffing box from the outside, but it’s needed on the inside between the packing and the shaft.

A lantern ring is used to get the water to the inside of the packing rings where the heat is being generated. The lantern ring is a metal ring that has holes in it. Water circulates around the outside of the lantern ring and passes through the holes to get to the inside of the packing rings. The lantern ring must be aligned with the seal water port on the stuffing box to make sure that water will get to the center of the stuffing box. Whenever a potable supply is used for a pump that is pumping non-potable water, an air gap or reduced pressure backflow preventer device must be used to prevent a possible cross-connection.

If there isn’t enough seal water moving past the packing and rotating pump shaft to cool them properly, the packing will overheat. If the packing is allowed to overheat, the lubricant in the packing will be driven away from the shaft and the packing will become glazed, much like nylon cord that has been burned at the end. The glazed packing will then start cutting into the shaft sleeve, creating more friction and heat. The result will be packing failure and a severely damage shaft sleeve.