Costs

The cost of a conventional gravity sewer system varies, based on many factors, including the depth and difficulty of excavation, the cost of labor, availability of pipe, geologic conditions, hydraulic grade line, and construction sequencing. As such, it is difficult to quantify the cost per linear foot for a particular sewer pipe size.

Pressure Sewer Systems

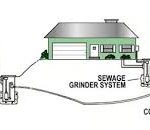

Pressure sewer systems are most cost effective where housing density is low, where the terrain has undulations with relatively high relief, and where the system outfall must be at the same or a higher elevation than most or all of the service area. They can also be effective where flat terrain is combined with high ground water or bedrock, making deep cuts and/or multiple lift stations excessively expensive. They can be cost effective even in densely populated areas where difficult construction or right of way conditions exist, or where the terrain will not accommodate gravity sewers.

Since pressure systems do not have the large excess capacity typical of conventional gravity sewers, they must be designed with a balanced approach, keeping future growth and internal hydraulic performance in mind.

Advantages

* Pressure sewer systems that connect several residences to a “cluster” pump station can be less expensive than conventional gravity systems. On-property facilities represent a major portion of the capital cost of the entire system and are shared in a cluster arrangement.

* This can be an economic advantage since on-property components are not required until a house is constructed and are borne by the homeowner. Low front-end investment makes the present-value cost of the entire system lower than that of conventional gravity sewerage, especially in new development areas where homes are built over many years.

* Because wastewater is pumped under pressure, gravity flow is not necessary and the strict alignment and slope restrictions for conventional gravity sewers can be relaxed. Network layout does not depend on ground contours: pipes can be laid in any location and extensions can be made in the street right-of-way at a relatively small cost without damage to existing structures.

Other advantages of pressure sewers include:

1. Material and trenching costs are significantly lower because pipe size and depth requirements are reduced.

2. Low-cost clean outs and valve assemblies are used rather than manholes and may be spaced further apart than manholes in a conventional system.

3. Infiltration is reduced, resulting in reductions in pipe size.

4. The user pays for the electricity to operate the pump unit. The resulting increase in electric bills is small and may replace municipality or community bills for central pumping eliminated by the pressure system.

5. Final treatment may be substantially reduced in hydraulic and organic loading in septic tank effluent pump systems. Hydraulic loadings are also reduced for grinder pump systems.

6. Because sewage is transported under pressure, more flexibility is allowed in sighting final treatment facilities and may help reduce the length of outfall lines or treatment plant construction costs.

Disadvantages

* Requires much institutional involvement because the pressure system has many mechanical components throughout the service area.

* The operation and maintenance (O&M) cost for a pressure system is often higher than a conventional gravity system due to the high number of pumps in use. However, lift stations in a conventional gravity sewer can reverse this situation.

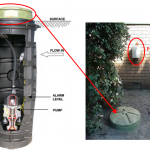

* Annual preventive maintenance calls are usually scheduled for grinder pump (GP) components of pressure sewers. Septic tank effluent pump (STEP) systems also require pump-out of septic tanks at two to three year intervals.

* Public education is necessary so the user knows how to deal with emergencies and how to avoid blockages or other maintenance problems.

* The number of pumps that can share the same downstream force main is limited.

* Power outages can result in overflows if standby generators are not available.

* Life cycle replacement costs are expected to be higher because pressure sewers have a lower life expectancy than conventional systems.

* Odors and corrosion are potential problems because the wastewater in the collection sewers is usually septic. Proper ventilation and odor control must be provided in the design and non-corrosive components should be used.

* Air release valves are often vented to soil beds to minimize odor problems and special discharge and treatment designs are required to avoid terminal discharge problems.