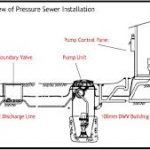

Pressure Sewer Systems (Design Criteria)

Many different design flows can be used in pressure systems. When positive displacement grinder pump units are used, the design flow is obtained by multiplying the pump discharge by the maximum number of pumps expected to be operating simultaneously. No allowances for infiltration and inflow are required. No minimum velocity is generally used in design, but grinder pump systems must attain three to five feet per second at least once per day. Pressure mains generally use 50 mm (2 inch) or larger PVC pipe (SDR 21) and rubber ring joints or solvent welding to assemble the pipe joints. High-density polyethylene (HDPE) pipe with fused joints is widely used in Canada. Electrical requirements, especially for grinder pump systems, may necessitate rewiring and electrical service upgrading in the service area. Pipes are generally buried to at least the winter frost penetration depth; in far northern sites insulated and heat-traced pipes are generally buried at a minimal depth.

Grinder pump and septic tank effluent pump pumps are sized to accommodate the hydraulic grade requirements of the system. Discharge points must use drop inlets to minimize odors and corrosion. Air release valves are placed at high points in the sewer and often are vented to soil beds. Both septic tank effluent pump and grinder pump systems can be assumed to be anaerobic and potentially odorous if subjected to turbulence (stripping of gases such as H2S).

Calculating Detention Time

What is the detention time in hours in an interceptor sewer ½ mile long and 24 inches in diameter if the average flow is 0.14 MGD?

Detention Time = (Volume, gal) / (Flow, gal/min)

First find the number of feet in ½ mile: 1 mile = 5280 feet, SO, 1/2 mile: (5280 feet) / (2) = 2640 feet

Convert diameter from inches to feet: (24 inches) / (12 in/ft) = 2 ft

Many of you use 3.14 X r X r (or 3.14 r2), so find the radius: (2 ft) / (2) = 1 ft radius

The formula for Cubic Feet is: 3.14 X R, ft X R, ft X Depth, ft , but in this case instead of depth we will use length, so complete the formula: 3.14 X 1ft X 1ft X 2640 ft = 8,289.6 cuft

(NOTE: You could have used the Diameter as follows – 0.785 X D’ X D’ X Length and get the same number)

Now you have Cubic Feet, but the numerator calls for the Volume in Gallons NOT Cubic Feet – so: 8,289.6 cuft X 7.48 gal/cuft = 62,006.208 gal

Convert MGD to gpm: 0.14 MGD X 1,000,000 = 140,000 gal/day The question asked for the result in gallons per hour, and the formula gives the flow in gal/min, so instead of taking the flow to minutes then back to hours, we will just stop at gal/hour as we convert our flow = (140,000 gal/day) / (24 hrs/day) = 5,833.33 gal/hr

Now work the given formula: (62,006.208 gal) / (5,8333.33 gal/hr) = 10.63 hrs

Calculating Flushing Time

A pipe from a subdivision is clogged. The main is 900 feet long and 12-inches in diameter. The pipe delivers an average flow of 50 ft3/min. The collection crew is flushing the main to remove the clog. How long should they flush the line to achieve 3 pipe volumes?

First calculate the Volume of the pipe: Cuft or ft3 (3.14 X R, ft X R, ft X Length, ft)

Convert inches into feet: (12 in) / (12 in/ft) = 1 ft

Radius is 1/2 the Diameter: (1 ft) / (2) = (0.5 ft) Radius

3.14 X 0.5 ft X 0.5 ft X 900 ft = 706.5 cuft this is the VOLUME in ft3

(OR you could have used Diameter: 0.785 X 1 X 1 X 900 ft = 706.5 cuft)

We need to achieve 3 pipe volumes, so multiply the pipe volume by 3,:

706.5 cuft X 3 = 2,119.5 ft3

Now divide that number by the average flow of 50 ft3/min (2,119.5 ft3) / (50 ft3/min) = 42.39 minutes