Vacuum Sewer Systems

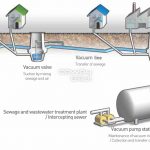

Vacuum sewers have become an acceptable alternative in the proper application and are providing efficient and reliable sewer service to communities all around the world. A vacuum sewer system consists of three major components: the valve pit, the vacuum mains, and the vacuum station.

Vacuum sewerage is a mechanized system of wastewater transport. Unlike gravity flow, vacuum sewers use differential air pressure to move the sewage. A central source of power to operate vacuum pumps is required to maintain vacuum (negative pressure) on the collection system. The system requires a normally closed vacuum/gravity interface valve at each entry point to seal the lines so that vacuum can be maintained. These valves, located in valve pits, open when a predetermined amount of sewage accumulates in collecting sumps. The resulting differential pressure between atmosphere and vacuum becomes the driving force that propels the sewage towards the vacuum station.

An early concept centering on liquid plug flow assumed that a wastewater plug completely sealed the pipe bore during static conditions. The movement of the plug through the pipe bore was attributed to the pressure differential behind and in front of the plug. Pipe friction would cause the plug to disintegrate, thus eliminating the driving force. Therefore, reformer pockets were located in the vacuum sewer to allow the plug to reform by gravity and thus restore the pressure differential. In this concept, the re-establishment of the pressure differential for each disintegrated plug was a major design consideration.

In the current saw-tooth profile design concept, the reformer pockets are eliminated so that the wastewater does not completely fill or “seal” the pipe bore. Air flows above the liquid, thus maintaining a vacuum condition throughout the length of the pipeline. In this concept, the liquid is assumed to take the form of a spiral, rotating, hollow cylinder. The momentum of the wastewater and the air carries the previously disintegrated cylinders over the downstream sawtooth lifts. The momentum of each subsequent air/liquid slug and its contribution to the progressive movement of the liquid component of the previous slugs are the major design considerations.

A vacuum created by vacuum pumps located at the vacuum station is transferred through the vacuum mains and to the valve pit. The valve pit is where the interface between gravity and vacuum occurs.

Housed in the top chamber of the valve pit is an interface valve. This valve is normally closed in order to seal the vacuum mains. This ensures that vacuum is maintained on the piping network at all times. The lower chamber of the valve pit is a sump that receives the sewage from the house. When sewage accumulates in the sump, the interface valve automatically opens. This is done without any electrical power being required. The valve opens and the contents of the sump are evacuated. The valve stays open momentarily to allow for atmospheric air to enter the system. This air comes from the air-intake located by the house.