Joining of Pipe

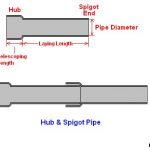

Most pipes in sanitary WW use a bell on one end and a spigot on the other and a resilient type gasket to make the joining of the bell and spigot watertight. The bell should be pointed upgrade when installing. The most resilient gasket is the “O” ring type sealed in a groove on the spigot or a of mating of rings precast in the bell and on the spigot.

Steps to join bell and spigot:

1. Clean bell and spigot

2. Lube gasket and place in position

3. Guide spigot end of pipe into bell

4. Push or pull pipe into place

5. Inspect joint and seating of gasket

6. Check alignment and grade

Costs for piping comparisons should include both the costs of the materials as well as the construction costs. The pipe cost is usually given in dollars per unit length, traditionally in $/linear foot, plus the costs of the fittings, connections, and joints.

Construction costs will depend on the type of digging necessary, special field equipment requirements, and an allowance for in-field adjustments to the system. Access to pipe systems will also be a relevant cost factor, as manhole spacing is dependant on pipe size. Sanitary sewer construction costs depend on several variables, including:

* Depth

* Type of soil

* Presence of rock

* Type of bedding material

* Location (rural vs. urban areas)

* Clearing costs

* Other factors

Typical pipe materials for small diameter sanitary sewers (8″ through 24″ diameter) include:

* PVC

* Vitrified clay

* Ductile iron

The following is typically not included in the cost per linear foot:

* Asphalt and gravel driveway repair.

* Open cut of roads.

* Boring and jacking.

* Concrete encasement of pipe at stream crossings or other locations.

* Erosion control.

* Relocation of other utilities.

Soil material is assumed to be silt, clay, or other soil mixtures with no requirement for shoring, rock removal, or dewatering.