Sludge Thickening and Dewatering

Even what is considered a “thick” sludge, (5 – 6% total solids), still contains over 90% water. Storing and transporting all the water along with the solids contained within it is not practical. For this reason, there are a number of methods of separating solids from water. These methods include; gravity thickeners, diffused air floatation (DAF) units, belt presses, centrifuges and sludge drying beds. Some of the methods are capable of thickening sludge, but it remains a liquid. Others can remove enough water that what is left is a semi-dry to dry solid. Some dewatering processes are located before digestion, others after. Most drying processes, like sludge drying beds, are only practical if located following digestion. Chemicals that are known as polymers can be used to enhance many of the sludge dewatering and drying processes.

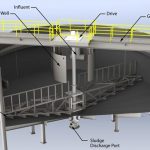

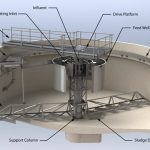

Gravity thickening of wastewater sludge uses the force of gravity to separate solids from water. Solids that are heavier than the water will settle to the bottom and be compacted by the weight of the overlying solids. Gravity thickeners are typically circular or square in design and resemble secondary clarifiers. Their main components include; a feed line and baffle for good flow distribution, a sludge rake mechanism to move the sludge to the bottom center of the tank for removal, vertical steel “pickets” mounted on the sludge rake, an effluent overflow weir, a scum box or tilting weir for removal of floating scum and solids, and a sludge withdrawal line.

The successful operation of gravity thickeners depends upon these factors:

1. Type of sludge being thickened. Primary sludge thickens best in gravity thickeners, but must not be allowed to become septic. Secondary sludge can be difficult to thicken in this type of process due to their lower solids content and denitrification.

2. Age of the feed sludge. Older sludges are prone to gasification caused by denitrification and gasses produced by septic conditions that cause sludge particles to float.

3. Sludge temperature. Warmer sludge does not settle as well because of gasification due to the increase in biological activity.

4. Sludge blanket depth. The thickening action is due in large part to the compaction that occurs from the overlying sludge. A balance must be struck between maintaining a thick enough blanket to achieve compaction and removing the solids before gasification.

5. Hydraulic and solids loading. The unit must be designed to handle the hydraulic and solids loading experienced.

Gravity thickeners are typically capable of thickening sludge to between 2 – 4%. Solids concentration as high as 6% can be achieved with the addition of polymers or other thickening agents, but it is important to know whether or not the sludge pump in use can remove concentrations that are this high.

Below is a Circular Clarifier and then a Gravity Thickener