Lift Stations

Force Mains Force mains are pipelines that convey wastewater under pressure from the discharge side of a pump or pneumatic ejector to a discharge point. Pumps or compressors located in a lift station provide the energy for wastewater conveyance in force mains.

The key elements of force mains are:

Pipe

Valves

Pressure surge control devices

Force main cleaning system

Force mains are constructed from various materials and come in a wide range of diameters. Wastewater quality governs the selection of the most suitable pipe material. Operating pressure and corrosion resistance also impact the choice. Pipeline size and wall thickness are determined by wastewater flow, operating pressure, and trench conditions.

Force mains may be aerated or the wastewater chlorinated at the pump station to prevent odors and excessive corrosion. Pressure surge control devices are installed to reduce pipeline pressure below a safe operating pressure during lift station start-up and shut-off. Typically, automatically operated valves (cone or ball type) control pressure surges at the pump discharge or pressure surge tanks.

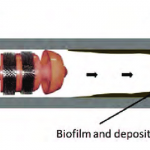

Normally, force main cleaning includes running a manufactured “pigging” device through the line and long force mains are typically equipped with “pig” insertion and retrieval stations. In most cases, insertion facilities are located within the lift station and the pig removal station is at the discharge point of the force main. Several launching and retrieval stations are usually provided in long force mains to facilitate cleaning of the pipeline.

Force mains are used to convey wastewater from a lower to higher elevation, particularly where the elevation of the source is not sufficient for gravity flow and/or the use of gravity conveyance will result in excessive excavation depths and high sewer pipeline construction costs.

Ductile iron and polyvinyl chloride (PVC) are the most frequently used materials for wastewater force mains. Ductile iron pipe has particular advantages in wastewater collection systems due to its high strength and high flow capacity with greater than nominal inside diameters and tight joints. For special corrosive conditions and extremely high flow characteristics, polyethylene-lined ductile iron pipe and fittings are widely used.

Cast iron pipe with glass lining is available in standard pipe sizes, with most joints in lengths up to 6.1 meters (20 feet). Corrosion-resistant plastic lined piping systems are used for certain waste carrying applications. Polyethylene-lined ductile iron pipe and fittings known as “poly-bond-lined” pipe is widely used for force mains conveying highly corrosive industrial or municipal wastewater.

The types of thermoplastic pipe materials used for force main service are PVC, acrylonitrile-butadiene-styrene (ABS), and polyethylene (PE). The corrosion resistance, light weight, and low hydraulic friction characteristics of these materials offer certain advantages for different force main applications, including resistance to microbial attack. Typically, PVC pipes are available in standard diameters of 100 to 900 mm (4 to 36 inches) and their laying lengths normally range from 3 to 6 meters (10 to 20 feet). The use of composite material pipes, such as fiberglass reinforced mortar pipe (“truss pipe”), is increasing in the construction of force mains. A truss pipe is constructed on concentric ABS cylinders with annular space filled with cement. Pipe fabricated of fiberglass reinforced epoxy resin is almost as strong as steel, as well as corrosion and abrasion resistant.

Certain types of asbestos-cement pipe are applicable in construction of wastewater force mains. The advantage of asbestos-cement pipes in sewer applications is their low hydraulic friction. These pipes are relatively lightweight, allowing long laying lengths in long lines. Asbestos-cement pipes are also highly corrosion resistant. At one time it was thought that many asbestos containing products (including asbestos-cement pipe) would be banned by the Environmental Protection Agency. However, a court ruling overturned this ban and this pipe is available and still used for wastewater force main applications (Sanks, 1998).

Force mains are very reliable when they are properly designed and maintained. In general, force main reliability and useful life are comparable to that of gravity sewer lines, but pipeline reliability may be compromised by excessive pressure surges, corrosion, or lack of routine maintenance.