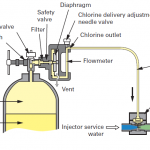

A gas chlorine system consists of one or more gas cylinders connected to gas chlorinator. The gas chlorinator consists of a pressure regulating valve, a feed rate indicator, a flow regulating device (a V-notch plug or needle valve), and an injector or ejector. The chlorine pressure-regulating valve (CPRV) opens when a vacuum is created by the injector and maintains a constant negative pressure inside the chlorinator. The feed rate indicator consists of a ball floating inside a glass tube. The feed rate is indicated on the glass tube and is read in “pounds per day.” The feed rate should be read at the widest point of the ball or bead. The feed rate is controlled using the needle valve or V-notch plug. Water flowing past the injector creates a vacuum that draws the gas into the system.

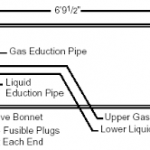

The maximum feed rate for gas drawn from a 150 lb. Cylinder is 40 pounds/day. The maximum gas feed rate for a 1-ton cylinder is 400 pounds/day. If these feed rates are exceeded, the tanks will frost over because heat can’t pass through the tanks as fast as it is used to evaporate the chlorine from a liquid to a gas. This can also occur in situations where several tanks are manifolded to the chlorinator. If one of the cylinder valves is partially closed the other tanks may try to feed too much gas and frost over. When this happens, check the tank that isn’t frosted for a closed valve or plugged pigtail line. Ton cylinders are sometimes set up to feed liquefied gas. These systems used an evaporator to change the liquid to a gas before it goes to the chlorinator. There is no limit to how much liquid chlorine can be removed from a cylinder since the heat for evaporation is supplied by an outside source. NEVER manifold cylinders together when feeding liquefied chlorine to an evaporator. Expansion tanks equipped with rupture disks are used to protect all liquid feed piping. These provide protection from expansion of liquefied gas that may become isolated in the line.

Chlorine Evaporators are installed in treatment plants where large quantities of chlorine are used. An evaporator is a hot water heater surrounding a steel tank. Water is usually heated by electricity. Heat in the water is transferred to the liquid chlorine in a inner steel tank. Water bath heaters are used to provide an even distribution of heat around the center tank to eliminate the problem of hot spots on the inner tank. Elimination of hot spots makes the evaporator easier to control and reduces the danger of overheating the chlorine and causing pressurization of chlorine by expansion.

Liquid chlorine containers are connected to the chlorine system through the liquid valve. When the liquid chlorine flowing from the container reaches the evaporator, the liquid chlorine vaporizes. Chlorine gas flows from the evaporator to the gas manifold.