Laboratory tests are critical for the efficient control of the wastewater treatment plant as well as for the effluent monitoring required by discharge permits. Having a laboratory at your disposal is one of the most valuable assets a wastewater operator can have. Good operators turn to the laboratory for much of the information they need to troubleshoot problems in the treatment process. In fact, laboratory data can often be used to prevent problems from developing in the first place. Most medium and large plants have a full time lab analyst and the necessary laboratory equipment to run most NPDES monitoring tests as well as most process control tests. Small systems typically have only a limited ability to run process control test and take all of their effluent monitoring samples to a contract laboratory (with the exception of pH and total residual chlorine, which must be analyzed immediately).

Many states require that lab analysts be certified. Laboratories and lab personnel that conduct monitoring test for NPDES in many states do not have to meet any certification requirements, however, laboratories that conduct drinking water analysis do. Lab experience does count toward operator certification (in many states, but it may be awarded at a different rate). Many lab analysts are also certified operators.

Many of the activities performed in wastewater treatment systems are dangerous, and working in the laboratory is no exception. Lab workers handle dangerous chemicals such as acid, bases and volatile compounds as well as infectious wastewater samples. Because of the hazards, it is important that lab workers consistently wear personal protective equipment (PPE) whenever appropriate. The PPE that is required for common daily tasks in the laboratory include; safety glasses, a face shield, goggles, rubber gloves and a lab coat. Laboratories themselves must be equipped with a variety of safety equipment. This equipment may include; a fume hood, an emergency shower and eyewash, fire extinguishers, a first aid kit and hazardous materials storage cabinets. Access to the laboratory should be limited (doors always closed during working hours and locked after hours).

Wastewater laboratories are filled with specialized instruments that must be used in a precise manner in order to obtain the desired accuracies. Understanding what level of accuracy is required is the first step in choosing what piece of equipment to use. Knowing which equipment delivers the desired level of accuracy is the second. Mastering the proper procedures and techniques associated with each instrument is also very important. The following is an overview of the basic lab procedures that all lab analysts should understand.

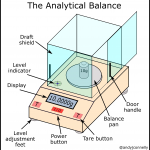

In the wastewater laboratory, the ability to precisely weigh items is very important. When a very high degree of accuracy is called for (+/- 0.1 mg), an analytical balance is used for weighing items. Other types of scales, such as a pan balance or a triple beam balance are used when less accuracy is needed. Whatever type of scale is used, it should be in good working order and checked for accuracy regularly. For analytical balances, this means verifying the accuracy against National Institute of Standards and Technology (NIST) certified Class 1 weights on a regular basis (generally monthly). It is also good laboratory practice to have balances checked and calibrated by an instrument service technician once a year.