Denitrification

The control of any biological denitrification process centers around three things:

(1) excluding dissolved oxygen,

(2) maintaining the proper detention time, and

(3) ensuring an adequate carbon source to drive the organisms to denitrify.

A D.O. meter is one of the most useful tools for troubleshooting denitrification systems. If any D.O. (>0.1 mg/L) is allowed to exist in the anoxic zone, denitrification will be hampered. Checking for the presence of dissolved oxygen with an accurately calibrated D.O. meter is one of the most fundamental process control checks.

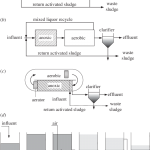

The detention time in the anoxic zone should be around 1 – 2 hours in order to ensure adequate denitrification. Detention times lower than 1 hour usually do not allow enough time for the complete utilization of any residual D.O. and for complete denitrification. Detention times that are excessive will overstress or even kill the strict aerobes in the system. The most sensitive obligate aerobes are the nitrifying bacteria. If they are killed off due to excessively long anoxic exposure, the entire nitrogen removal process will fail. Mixed liquor recycling is used to maintain the desired detention times for separate sludge systems and pre-denitrification systems.

For SBRs, the denitrification detention time is a function of the length of the anoxic phase, which can be adjusted by the operator. It is often necessary to increase the length of the anoxic phase of an SBR during the winter months, when cold temperatures make oxygen easier to dissolve and slow the metabolism of the microbes. Conversely, the length of the anoxic phase can often be shortened during warm weather.

Ensuring an adequate source of carbon is generally not a problem, because the influent contains all of the carbon that is needed to drive the denitrification process. However, for some configurations (particularly separate sludge post-denitrification), it may be necessary to add a additional carbon source. In the past, methanol was used for this purpose, however, the cost and complication of methanol injection almost always make the use of influent as a carbon source much more desirable.